A Snapshot Review is a spare parts management health check that will deliver a plan to improve your spare parts management outcomes.

The review will uncover the strengths and weaknesses in your spare parts management processes and systems and then identify the constraints that limit your company’s ability to achieve your spare parts inventory management goals.

From this, a plan for achieving your goals is developed.

- What are the ‘root causes’ of the current spare parts management issues?

- Which potential actions will have the most impact on improvement but also deliver sustainable outcomes?

- What is the logical sequencing of actions to deliver the desired outcomes?

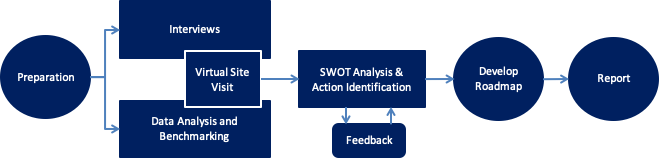

- Interviews with key team members

- Data analysis to identify the priority issues with your current inventory holdings

- Benchmarking of your company against our database of +120 companies

- Application of our Best Practice Matrix – tool that let’s you know where you REALLY stand!

- A site review – conducted ‘virtually’ utilizing video services such as WhatsApp or FaceTime

- Policy analysis to examine both the content and the coverage of your policies

- SWOT analysis identifying Strengths, Weaknesses, Opportunities, and Threats

- Root Cause Analysis – all of the above feeds into an RCA, which summarized the factors driving your root causes

A modern consulting engagement for spare parts inventory management, delivered through secure digital channels and focused on measurable operational and financial outcomes.

A modern consulting engagement for spare parts inventory management, delivered through secure digital channels and focused on measurable operational and financial outcomes.

All data and policy analysis is completed from our office.

On commencement of a Snapshot Review we will advise of the full data requirements.

A Snapshot Review is usually be completed in 6-8 weeks. The main determinant of time is the availability of your team and data.

- Detail of the results of each analysis.

- Specific recommendations on the actions that your company should pursue to achieve its inventory management goals.

- Prioritization and sequencing of the actions.

- A high-level roll-out plan that will be specific in terms of sequence and importance.

This is a structured and proven program of work that will provide a plan for the required changes and improvements.

Phillip Slater used his Snapshot Review process to create a framework for improving our materials management. Phillip’s input and guidance was key factor in helping us move from where we were to a greatly improved environment.

Pam Godden

Corporate Services Manager

V/Line Transport